#Automatic Paper Core Cutting Machine

Explore tagged Tumblr posts

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

How Restaurant Asset Management Software Boosts Profitability and Reduces Downtime

Running a successful restaurant goes far beyond just serving delicious food. Behind the scenes, efficient management of kitchen equipment, appliances, and other assets plays a critical role in maintaining smooth operations and maximizing profits. Unfortunately, many restaurants still rely on outdated methods like spreadsheets and physical records to track maintenance and repairs — which can lead to costly equipment failures and operational downtime.

That’s where restaurant asset management software comes in. By digitizing and automating asset tracking and maintenance workflows, restaurants can reduce downtime, control costs, and boost overall profitability. In this blog, we’ll explore how smart asset management software, like Ezist, is transforming restaurant operations across the USA.

Why Traditional Asset Tracking Falls Short in Restaurants

From interviews with restaurant branches, several key pain points were identified:

Spreadsheets and Paper Records: Many restaurants still use manual spreadsheets and physical files to track invoices, service requests, and budgets. This approach is prone to data loss and human error.

No Real-Time Updates: Without digital tools, managers lack visibility into service statuses and equipment conditions, leading to delayed repairs and reactive maintenance.

Manual Coordination: Scheduling repairs and managing service providers often involve back-and-forth calls and emails, consuming valuable time and increasing the risk of missed appointments.

These issues lead to unplanned equipment breakdowns, causing kitchen delays, frustrated staff, and unhappy customers — all negatively impacting the restaurant’s bottom line.

How Restaurant Asset Management Software Changes the Game

1. Centralized Asset Tracking and Digital Records

Software like Ezist offers a centralized dashboard to track every piece of equipment — from ovens and refrigerators to coffee machines and POS devices. It eliminates the need for paper trails by digitizing receipts, warranty info, and maintenance history, all stored securely in the cloud.

2. Automated Maintenance Scheduling & Alerts

By automating preventive maintenance reminders, restaurants can service equipment before failures occur. Timely alerts for upcoming warranty expirations and service appointments mean no more missed maintenance deadlines — significantly reducing unexpected downtime.

3. Streamlined Repair Requests and Vendor Management

Ezist’s app enables staff to submit service requests instantly, with automatic scheduling and status tracking. It also consolidates vendor contracts and invoices, making it easier to evaluate service provider performance and control repair costs.

4. Mobile Access for On-the-Go Management

Restaurant managers and maintenance teams can access asset info anytime via mobile devices, enabling quick decisions and real-time updates even during busy service hours. This flexibility ensures faster responses and smoother kitchen operations.

Real Results: Boost Profitability and Cut Costs

Restaurants using asset management software have reported:

Reduced Equipment Downtime: Proactive maintenance cuts unexpected breakdowns by up to 40%, preventing costly service disruptions.

Lower Maintenance Expenses: Automated tracking and vendor management helps identify inefficient service providers and avoid unnecessary repairs.

Improved Budget Control: Digital receipts and expense categorization simplify budgeting and financial planning.

Increased Staff Productivity: Eliminating manual paperwork frees up staff to focus on customer service and core restaurant tasks.

Investing in asset management technology isn’t just about avoiding problems — it’s about unlocking growth opportunities through operational excellence.

Why Choose Ezist for Your Restaurant?

Ezist is designed specifically to address the challenges faced by restaurants and small businesses by offering:

Smart, cloud-based asset tracking with multi-device access

Automated warranty and maintenance alerts

Simple in-app repair requests and vendor tracking

Customizable workflows to fit your restaurant’s unique needs

Secure data storage with privacy-first design

Whether you run a single restaurant or multiple branches, Ezist helps you keep your kitchen running smoothly, reduce downtime, and increase profitability.

Ready to Boost Your Restaurant’s Efficiency and Profits?

Don’t let outdated manual processes hold you back. Experience the power of smart asset management with Ezist and transform how you maintain your restaurant’s equipment.

👉 Get started for FREE today!

Register now: Ezist Registration

Download the app on iOS: Apple App Store

Download the app on Android: Google Play Store

FAQs About Restaurant Asset Management Software

Q1: How does asset management software reduce equipment downtime? A: By automating maintenance schedules and sending timely alerts, it ensures repairs and servicing happen before equipment fails.

Q2: Can I track warranty information with the software? A: Yes, Ezist automatically tracks warranties and notifies you before they expire, making warranty claims easier.

Q3: Is the software accessible on mobile devices? A: Absolutely. You can manage assets and maintenance tasks from smartphones, tablets, or desktops anytime, anywhere.

Q4: Can multiple users access the system? A: Yes, Ezist supports multi-user access with role-based permissions, allowing staff and vendors controlled access.

Q5: Will using asset management software save money? A: Yes, by reducing breakdowns, optimizing repairs, and improving budgeting, it significantly lowers maintenance costs over time.

If you want to stay ahead in the competitive restaurant industry, effective asset management is a must. Start your free trial with Ezist today and watch your restaurant thrive!

0 notes

Text

Why Payables Outsourcing Is Transforming Finance Operations

Businesses today are expected to be more agile, cost-effective, and technologically advanced than ever before. One area that directly impacts operational efficiency and vendor relationships is payables management. With increasing invoice volumes and complexity in vendor terms, many companies are embracing payables outsourcing as a way to streamline their finance operations.

Payables outsourcing involves transferring the responsibility of invoice processing, payment scheduling, compliance tracking, and vendor communication to a specialized service provider. These partners use cutting-edge tools and a skilled workforce to handle high volumes of transactions with unmatched precision and speed. By doing so, businesses not only save time and reduce costs but also mitigate compliance risks and improve vendor satisfaction.

A core benefit of payables outsourcing is the consistency it brings to the procure-to-pay process. Vendors receive their payments on time, reducing friction and fostering trust. This is especially important for companies with large vendor networks or international suppliers, where compliance with local regulations and currency differences can complicate in-house operations. Outsourcing partners offer local expertise and tools to manage multi-country payables seamlessly.

When payables are managed internally, the process often involves multiple departments and can be riddled with bottlenecks. From invoice receipt to approval workflows to final payment, delays are common. In contrast, payables outsourcing services bring automation and standardization to the process. Invoices are scanned, digitized, and routed electronically for approvals. Payment cycles are automatically aligned with vendor terms and company cash flow, reducing human errors and improving financial predictability.

Outsourcing payables also improves financial visibility. With real-time dashboards and analytics, CFOs can track pending liabilities, understand spending patterns, and make informed cash flow decisions. This improved visibility is essential for planning, forecasting, and avoiding last-minute cash crunches. Companies can also implement stronger internal controls, ensuring every payment is authorized, traceable, and compliant with corporate policies.

Another key advantage of payables outsourcing is cost reduction. By eliminating the need for large in-house teams, reducing paper-based processes, and minimizing late payment penalties, businesses can achieve significant cost savings. In some cases, companies have reported savings of up to 60% on their accounts payable function after outsourcing. These savings can then be reinvested in strategic initiatives, innovation, or market expansion.

Payables outsourcing is often part of a broader bpo accounting process, where multiple finance functions are outsourced for maximum efficiency. These can include accounts receivable, payroll, general ledger, and reporting. With a unified BPO accounting partner like RightPath Global Solutions, companies enjoy better data integration, faster reporting, and smoother audits. This holistic approach enhances organizational agility and ensures that the finance department is not bogged down by transactional tasks.

In addition to efficiency, compliance is another area where outsourcing shines. Financial regulations around the world are becoming more stringent. Payables outsourcing firms stay updated with evolving tax rules, reporting standards, and audit requirements, ensuring your operations remain compliant. They also offer robust documentation, audit trails, and approval logs, simplifying the year-end closing and audit process.

Another benefit is access to advanced technology. Outsourcing partners use best-in-class ERP integrations, AI-powered fraud detection, and cloud-based platforms that offer mobile access and real-time tracking. Machine learning continuously improves invoice matching and anomaly detection, resulting in cleaner books and more accurate financial reporting. These are capabilities that many mid-sized businesses cannot develop internally due to budget or resource constraints.

One example of success comes from a retail chain with over 150 locations. After facing recurring vendor complaints, missed payments, and poor cash flow planning, they opted for payables outsourcing. Within six months, their invoice processing time was cut by half, vendor relationships improved, and the finance team could spend more time on analytics rather than approvals. Additionally, automation reduced manual errors and ensured adherence to vendor contract terms.

For businesses considering this move, it’s important to choose a provider with domain expertise, a proven track record, and strong technological infrastructure. Look for firms that offer SLA-driven performance, 24/7 support, multilingual capabilities, and customizable workflows. The right partner will not just process your invoices—they will become a strategic ally in your financial journey.

In closing, payables outsourcing is no longer just a trend; it’s a transformative strategy. It brings speed, accuracy, compliance, and insight into the financial operations of any business. Combined with broader BPO accounting processes, it becomes a powerful tool to drive operational excellence and long-term growth. As technology continues to evolve and businesses strive for greater efficiency, outsourcing key finance functions will become a competitive necessity rather than an optional enhancement.

0 notes

Text

Revolutionizing Packaging: The Versatile World of Paper Bag Making Machines

In recent years, paper bag making machines have emerged as key players in the packaging industry. With increasing global awareness surrounding environmental sustainability and the pressing need to reduce plastic waste, these machines have facilitated a shift toward paper-based alternatives. From grocery stores to fashion outlets, paper bags are becoming ubiquitous, and their production relies heavily on advanced technology.Get more news about paper bag making machine,you can vist our website!

At their core, paper bag making machines automate the entire manufacturing process, ensuring efficiency, consistency, and scalability. These machines can produce various types of bags, including flat-bottom bags, satchel bags, and multi-layer bags for industrial applications. Customization is another major advantage, allowing manufacturers to design bags with unique dimensions, colors, logos, and handles to meet specific client needs.

The production process typically begins with raw materials like kraft paper, chosen for its strength and eco-friendliness. The machine feeds, cuts, folds, and glues the paper into the desired shapes and sizes, employing advanced mechanisms like rotary dies and servo motors. Many machines also integrate printing units for branding purposes, making them a one-stop solution for businesses aiming to package products attractively.

One remarkable feature of modern paper bag making machines is their adaptability to diverse industries. In the food sector, they produce grease-resistant bags used for baked goods and fast food. In retail, they create aesthetically pleasing bags that enhance a brand’s image. In agriculture, they provide durable packaging for products like seeds and grains. The versatility ensures that these machines remain relevant across a wide array of applications.

Moreover, paper bag making machines play an essential role in addressing environmental challenges. Unlike plastic bags, paper bags decompose easily and can be recycled, making them a sustainable alternative. Many machines are designed to minimize waste during production, further contributing to eco-friendly practices. Some manufacturers have even adopted energy-efficient technologies to reduce their carbon footprint, aligning their operations with global environmental standards.

Economic benefits are another major draw. Businesses investing in paper bag making machines enjoy high-speed production capabilities that reduce labor costs and meet growing consumer demand. For small businesses, compact and semi-automatic models provide affordable options without compromising on quality.

However, challenges remain. The production of paper bags requires raw materials, and deforestation can become a concern if not managed responsibly. Many companies are addressing this by sourcing paper from sustainable plantations or recycling existing paper products. Additionally, the initial investment for purchasing advanced machines can be significant, although the long-term benefits often outweigh the costs.

In conclusion, paper bag making machines are instrumental in shaping the future of sustainable packaging. They offer a blend of technological innovation, environmental consciousness, and economic viability, helping industries transition from harmful plastics to eco-friendly alternatives. As technology continues to evolve, the capabilities of these machines are likely to expand, further cementing their role in creating a greener planet.

0 notes

Text

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

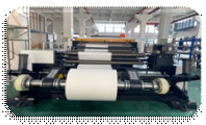

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Text

Profile Wrapping Machine: A Comprehensive Overview

A profile wrapping machine is a specialized piece of equipment used in various industries, particularly in the production of wood, plastics, and composite materials. These machines are designed to apply a veneer, laminate, or decorative film to the surface of profiles, which are typically shapes like edges, mouldings, and trim pieces. This process is essential for enhancing the appearance of products, providing surface protection, and adding unique texture and finishes.

The profile wrapping machine uses a combination of mechanical, thermal, and adhesive systems to wrap a material, often a paper, PVC, or melamine, around a workpiece. These machines are widely used in the woodworking, furniture, and door manufacturing industries, as well as in the production of automotive trim and various other consumer goods. The result is a seamless, high-quality finish that improves both the durability and aesthetic of the product.

Key Features of Profile Wrapping Machines

Profile wrapping machines are built to handle a variety of tasks, and their design is optimized for both precision and speed. Some of the key features include:

Feeding System: The feeding system is the mechanism that moves the profile through the machine. This system is designed to ensure smooth and consistent movement, preventing misalignment or damage to the workpiece. It includes rollers, belts, or conveyors that hold and transport the profiles.

Adhesive Application: One of the core features of the profile wrapping machine is the adhesive application system. Adhesive is applied to the workpiece surface to bond the wrapping material to it. The adhesive can be applied in different ways, such as by roller coating, spray, or direct application. The precise application of adhesive is critical to achieving a smooth, consistent finish.

Wrapping Mechanism: The wrapping unit is responsible for applying the film or veneer to the profile. This can be done with different techniques, including manual and automatic systems, depending on the machine. In automated systems, the material is fed from a roll, ensuring a continuous wrap without interruptions. The wrapping process should ensure that the material is applied tightly, without wrinkles or gaps, and that it adheres firmly to the profile.

Drying System: After the adhesive is applied, the profile may need to pass through a drying system to ensure that the adhesive cures properly. Some machines incorporate infrared or hot air drying to speed up the process and improve bonding efficiency.

Trimming and Cutting: Once the wrapping is complete, the profile may be trimmed to remove any excess material. This ensures that the wrapping fits the profile perfectly. Trimming units are incorporated into the machine, using rotating knives or cutting blades to ensure precise cuts.

Control Panel: Modern profile wrapping machines often come with an advanced control panel that allows operators to set various parameters, such as speed, adhesive application, temperature settings, and the type of wrapping material. This gives operators flexibility in adjusting the machine for different types of profiles and materials.

Roller and Pressure Units: To ensure proper adhesion, profile wrapping machines use rollers or pressure units that apply uniform pressure to the wrapped material. This helps eliminate air bubbles and ensures that the wrapping adheres evenly across the surface.

Material Options: Profile wrapping machines can be used with a wide range of materials, including paper, PVC, melamine, wood veneer, aluminum, and other decorative films. This gives manufacturers flexibility in choosing the material that best suits the desired finish and function.

1 note

·

View note

Text

How Alligator Automations Helps in Reducing Manual Labour Through Technology

Automation has become a core driver of productivity, shifting from a futuristic idea to an essential part of modern industry. Tasks once handled manually, especially repetitive ones, are now managed by intelligent machines, revolutionizing manufacturing, packing, and distribution processes. Alligator Automations is a leader in this shift, delivering cutting-edge solutions that streamline industrial workflows. Imagine a busy factory floor: products moving on conveyors, robots assembling intricate devices, and a synchronized packaging system—all showcasing automation’s potential. This vision of seamless collaboration between humans and machines has now become a reality due to companies like Alligator Automations.

From Humble Beginnings to Industry Leaders

Founded in 2008, Alligator Automations started with competition-based robotics and has evolved into a major player in end-of-line packaging automation. Committed to driving innovation, we provide automated solutions to diverse sectors like automotive, food and beverage, FMCG, agriculture and many more, positioning ourselves as a leader in industrial transformation.

How Alligator Automations Reduces Manual Labour in Key Areas

Advanced Palletizing Systems: Handling heavy palletizing loads manually is labour-intensive and risky. Alligator Automations’ robotic palletizers streamline this process, reducing worker strain and injuries while adapting to varied product shapes and weights. With robotic precision, companies can achieve high palletizing efficiency with minimal labour.

Automated Sorting & Product Handling: Our advanced systems use vision recognition to automate sorting, a valuable feature for industries like food and beverage, chemical, retail and many more, which demand high precision and hygiene. Automation enhances sorting accuracy, reduces manual input, and improves operational speed.

Bulk Material Bagging Solutions: For sectors like agriculture and construction, Alligator’s automated bagging systems manage bulk materials quickly and efficiently, reducing contamination, spillage, and wastage. This enhances productivity and safety on bagging lines, thus reducing manual labour through technology.

Improved Safety & Cost Savings: Automation reduces repetitive tasks and heavy lifting, lowering workplace injuries and labour costs. Alligator’s robotics improve safety and meet industry standards, making the work environment secure and efficient.

Data-Driven Production Insights: Alligator Automations’ IoT-enabled systems track real-time productivity, helping businesses optimize operations and asset maintenance. This AI-driven monitoring minimizes human oversight, ensuring seamless and efficient process control.

Applications Across Industries

Alligator Automations’ solutions cater to diverse industries, from FMCG and food production to warehousing, agriculture to automotive and many more. These automation solutions address unique pain points and labour-intensive tasks in each sector, allowing companies to scale their operations efficiently. For example:

Food & Beverages: Automation solutions like automatic bagging, secondary packaging, and intralogistic conveyor systems ensure compliance with food safety and quality standards.

Cement: Transitioning to automated packaging increases precision and operational speed.

Chemicals & Fertilizers: Safe handling systems reduce risks associated with hazardous materials.

Tyre Industries: Specialized systems streamline tyre manufacturing and handling.

Petrochemical, FMCG, Agro Commodities, Appliances, Automobile, E-commerce, Oil & Paints, Papers & Battery, and Seed industries benefit from enhanced packaging, palletizing, and intralogistics solutions tailored for high efficiency, safety, and reliability in each application.

Embrace Future-Ready Production with Alligator Automations

As labour shortages and operational costs rise, adopting automation becomes not just beneficial but essential. Alligator Automations empowers industries to enhance productivity, safety, and precision. By transitioning to automated systems, companies can significantly cut down on manual labour, streamline processes, and gain a competitive edge in today’s technology-driven market.

For an in-depth assessment and solution tailored to your production line, reach out to Alligator Automations today and explore the future of intelligent, labour-free automation.

#alligator automations#bagging machine#agatha harkness#packaging machine manufacturer#automatic conveyor systems

0 notes

Text

Sanitary Napkin Manufacturing Plant Report – Business Plan & Setup

Sanitary napkins are an essential hygiene product used by millions of women worldwide. With the growing awareness of menstrual hygiene and government initiatives promoting affordable sanitary products, the demand for sanitary napkins is increasing rapidly. Setting up a sanitary napkin manufacturing plant can be a profitable business venture with significant growth potential. This article provides a sanitary napkin manufacturing plant project report covering business plans, setup requirements, cost estimation, and profit margins.

Market Overview of Sanitary Napkin Manufacturing

The global sanitary napkin market is expected to witness substantial growth due to increasing awareness, improved affordability, and innovative biodegradable products. Key factors influencing the market include rising female population and awareness about menstrual hygiene, government programs promoting sanitary hygiene products, increasing preference for eco-friendly and biodegradable sanitary napkins, and the growth of e-commerce platforms enabling easy accessibility.

Business Plan for Sanitary Napkin Manufacturing Plant

Business Model

The business can operate under different models, such as small-scale or cottage industry, where sanitary napkins are manufactured on a small scale with manual or semi-automatic machines. Medium-scale industries use automated machinery to produce high-quality napkins at a competitive price. Large-scale industries set up fully automated plants with high production capacity and multiple product variations.

Target Audience

The primary customers for a sanitary napkin manufacturing business include retail stores and supermarkets, pharmacies and medical stores, schools, NGOs, and government initiatives, as well as e-commerce platforms and direct-to-consumer sales.

Location Selection

Choosing the right location is crucial for the business. A suitable location should have easy access to raw materials and suppliers, proximity to target markets for quick distribution, adequate water and electricity supply, and affordable labor availability.

Legal Requirements

To establish a sanitary napkin manufacturing business, compliance with legal regulations is necessary. Business registration options include sole proprietorship, partnership, or private limited company. Additionally, GST registration and tax compliance, manufacturing licenses, quality certifications from the Bureau of Indian Standards (BIS) or other relevant authorities, and environmental clearance (if chemical-based production methods are used) are required.

Setup Requirements for a Sanitary Napkin Manufacturing Plant

Raw Materials Required

The key raw materials for manufacturing sanitary napkins include absorbent core material such as fluff pulp or super absorbent polymer (SAP), a non-woven fabric top sheet for comfort, a polyethylene back sheet for leakage protection, adhesive for securing layers and wings, release paper to cover the adhesive surface, and packaging materials like individual wrappers and bulk packaging.

Machinery and Equipment

The manufacturing process requires several machines, including a pulp making machine to convert raw pulp into absorbent material, a napkin forming machine that shapes the napkins with layers, a sealing and cutting machine to seal edges and cut napkins to size, a sterilization unit to ensure hygiene and eliminate bacteria, and a packaging machine to wrap and seal napkins for sale.

Manufacturing Process

The manufacturing process begins with pulp preparation, where wood pulp is processed to form an absorbent core. Next, the absorbent core is sandwiched between the top and back sheet in the layering stage. The napkins are then sealed, shaped, and cut during the sealing and cutting stage. Afterward, they go through sterilization to ensure hygiene and maintain product quality. Finally, the napkins are packaged and prepared for distribution.

Sanitary Napkin Manufacturing Plant Project Report: Cost & Investment

The cost of setting up a sanitary napkin manufacturing plant varies based on location, production capacity, and the level of automation. The main cost components include land and building expenses, which range from approximately $20,000 to $50,000. The cost of machinery and equipment can range from $30,000 to $100,000, while raw materials require an investment of around $10,000 to $30,000. Labor and wages may cost between $5,000 and $15,000 per month. Marketing and distribution expenses could be around $5,000 to $20,000, with miscellaneous costs ranging from $5,000 to $15,000. Overall, the total investment is estimated to be between $75,000 and $230,000.

Profitability & ROI

The production cost per napkin typically ranges between $0.05 and $0.15, while the selling price is between $0.20 and $0.50. This results in a profit margin of approximately 30% to 50%. The breakeven period for the business is generally between 12 to 24 months, depending on market demand and operational efficiency.

Marketing & Distribution Strategy

Branding & Packaging

Attractive and eco-friendly packaging plays a crucial role in attracting customers. Highlighting unique selling points such as biodegradable materials, skin-friendliness, and ultra-thin designs can help establish brand identity.

Sales & Distribution Channels

To reach a wider audience, businesses should partner with retailers, pharmacies, and supermarkets. Selling through e-commerce platforms such as Amazon, Flipkart, and Shopify can further enhance reach. Collaborating with NGOs and government schemes can also help expand distribution networks.

Advertising & Promotions

Effective advertising strategies include digital marketing through social media, blogs, and influencer collaborations. Conducting awareness campaigns in schools and rural areas can help promote menstrual hygiene and boost sales. Offering discounts and loyalty programs for bulk buyers can also encourage repeat purchases.

Conclusion

Setting up a sanitary napkin manufacturing plant is a promising business venture with high demand and profitability. With a proper business plan, appropriate investment, and strategic marketing, entrepreneurs can establish a successful brand in the hygiene industry. The sanitary napkin manufacturing plant project report should include market research, setup costs, legal compliance, and production planning to ensure smooth operations and long-term success.

If you’re looking to start a sanitary napkin manufacturing business, this guide provides a detailed roadmap to help you plan and execute your venture effectively.

#sanitary napkin manufacturing plant project report#sanitary napkin manufacturing project report#sanitary pad project report

0 notes

Text

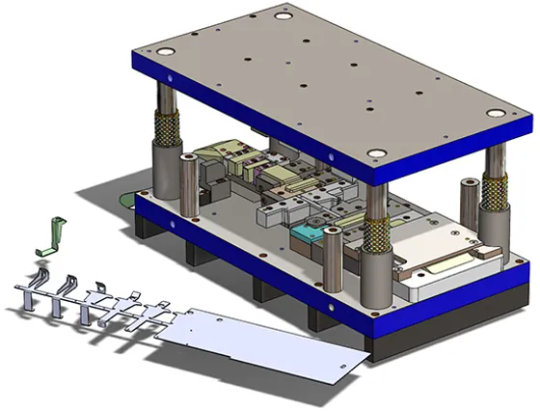

Custom Cutting Dies: High-Precision Tools for Accurate and Efficient Production

It can be said that in manufacturing industry, accuracy and speed are the keys to success. This is especially true for the industrial area where material such as paper, rubber or plastic require distinguishing in order to match particular specifications. This reality underlines the significance of custom cutting dies within the setting up of both uncooked and semi-end products in response to their particular calls for.

• Unparalleled Precision: Produce specific thinning attachments, where the fabricators obtain highly accurate designs of the needed forms because of cutting machines. They have boiled it down to a science and pushed doors to new levels of belief, it is unimagined.

• Enhanced Efficiency: Use of custom cutting dies helps to minimize wastage of cloth material and at the same time increase on production. They can just healthy into automatic machines to make the production faster without compromise the standard.

• Tailored Solutions: Writing about client slicing dies, Armstrong asserted that their big strength is that they could meet certain, specific needs. In any case, design or cloth, custom dies make up a specialized answer with flexibility to be an important tool in numerous fields.

Custom cutting dies have converted the manufacturing procedure, offering an amalgamation of performance, precision and adaptableness. With the proper custom slicing die, the opportunities

are infinite, fueling creativity, and pushing the boundaries of what can be accomplished in layout and manufacturing techniques.

Driving Transformation: Special Focus on the Automotive Stamping Companies

The world of the car enterprise is currently expanding and going through the change of the new horizons of improve, ergo, performance, and sustainability. When examining the vast array of procedures that instill life to our motors, one way remains discreet and obscured from our eyes yet it gives definition to the sophisticated beauty and potency of the motor – automotive stamping companies.

• Advancements in Automotive Stamping

Automotive stamping organizations, in large part unsung heroes, extensively have an impact on the very last product's excellent, integrity, and lifeline. These agencies have relentlessly championed many technological improvements together with excessive-velocity stamping and modern die stamping, steering the car enterprise toward remarkable product precision and cost effectiveness.

• Global Impact and Sustainability

There’s an increasing name for lighter, more potent, and more sustainable motors, forcing the industry to be seeking for new materials and sophisticated strategies. In response, stamping groups worldwide are adopting high-strength, lightweight steels and precision stamping technology, to deliver awesome overall performance at the same time as additionally lowering environmental effect.

• The Future Road-map

With the appearance of electric automobiles (EVs) and autonomous using, the call for unique additives and complicated shapes is surging. To meet those needs, automobile stamping agencies are actually moving gears toward extra flexible manufacturing methods and pioneering the adoption of AI and robotics, which paint a vibrant image of the future dynamics inside the automobile enterprise.

Cutting-Edge Success: The Mastery Behind Cutting Die Manufacturers

Explored the sector of precision engineering and original equipment’s manufacturing fit on the core of manufacturing company, the cutting die makers. These pioneers shape and fashion the most complex structures with great accuracy, creating great expectations internally the overall production assembly around the world.

• Expertise in Quality and Precision: Die reducing producers occupy the middle level in a world that never ceases to pursue the ideal. Due to the ability to shape, thin and inscribe materials made of paper, plastic, fabric, and metal those industry specialists provide high-quality performance products to a range of sectors.

• Technological Innovation at its Finest: The die cutting industry tends to be dynamic most of the time with fresh trends and inventions reddening working environments. Die slicing now requires advanced AI tooling and modern equipment, leading to increased competency and higher than expected performance in shipping products out.

• Environmental Stewardship: The reducing producers are not only obsessive about potency and quality but also about sustainability. Understanding their roles in sustaining our environment, they have equal applied environmental solutions to their operations. These include energy conserving devices and systems as well as ways and means of minimizing the amounts of wastes.

The cutting die manufacturers are real experienced players in their industry. Anchoring definition: The manufacturers who set the highest standards when creating the components with precision, adopting new technological advancements and engaging in deliberate and sustainable environment-friendly production practices are the backbone of several industries.

Innovative Excellence: Unveiling the Importance of a Leading Tool Manufacturing Company

Sailing through the relatively now somewhat a more threatening market of today requires nothing less than optimal performance and accuracy and creativity. And this is exactly in which device production companies make a quintessential entry. The accuracy and depth of their work means that they are not limited simply to the creation of equipment: the industries in which they are located put them right there at the center of many areas.

Tool Manufacturing Company is one such organization and the key pioneer for the development of device manufacturing and precision engineering brand. It is the symbol of innovation, nice and consistent value delivery.

• Innovation-Driven: we are at the modern-day of the era in which we offer excellent solutions that drive development for industries. The R& D of their company is inconstant striving — to develop liberal apparels that fulfill the new needs of an unexpectedly progressing society.

• Continuous Improvement: Self-imposed pressures of search for perfection and desire to innovate on their products and services placed us. Apart. Extending from revamping their manufacturing manner to similarly optimizing the capability of their equipment, they assigned a superior price to continual improvement.

The manufacturing organizations of tools – of which we are part – are not just suppliers; we are partners in progress. They occupy a main and unique position in modernization of processes, increase of efficiency and utilizing potential improvements for defining further development in industries.

Unveiling the Titans of tool Manufacturing Companies

In the context of global industrialization, the tool manufacturing enterprise bureaucracy one of the primary cogs within the wheel. Tool manufacturing companies serves as a basis stone for lots economic sectors via offering the important device to execute diverse important duties.

• We stand as one of the main giants in the tool manufacturing international. Known for its vast range of mining and production gadget, we embodies a spirit for innovation and satisfactory and is recommended for his or her use of superior era.

• No dialog about the tool manufacturing enterprise is ever entire without the point out of us. With a lineage spanning over many years, their recognition for delivering exceptional nice and sundry product traces stays unscathed.

These companies are not simply commercial enterprise entities but spearheads of the tool manufacturing region. They have an impact on industry traits and global manufacturing requirements at the same time as offering reliable, revolutionary, and exquisite products that lead the way in shaping the future of several industries.

Conclusion

Success in the industrial sector depends on precision and speed, especially when working with materials like plastic, rubber, and paper. Custom cutting dies revolutionize the production process by providing unmatched precision, increased productivity, and customized solutions. By promoting technical advancements, using lightweight, high-strength steels, and using precision stamping technology, automotive stamping businesses are revolutionizing the sector. With the emergence of electric cars and autonomous driving, they are also concentrating on the future of the auto industry.

Offering a variety of stamping die offerings and manufacturing alternatives, Metal Stamping Dies is dedicated to supporting you locate the ideal solutions on your local desires. We have interaction with all applicable parties to maximise your ROI and provide brilliant value. Our customizable services are designed to decorate your business operations and pressure success.

Contact us at (647) 294-5240 or through e mail at [email protected] to examine more or book an appointment.

0 notes

Video

youtube

full automatic washi tape, paper, film rewinding machine, automatic cut,...

full automatic washi tape, paper, film rewinding machine, automatic cut, labelling, paper core feed

0 notes

Text

Paper Roll Making Machine in Patna by Arya Industries

Arya Industries known for its high-quality Paper Roll Making Machines in Patna that cater to the needs of businesses involved in the paper industry. With years of experience and expertise, Arya Industries has established itself as the leading provider of paper roll making machines, offering innovative and reliable solutions to paper manufacturers in Patna and beyond.

Quality and Precision

At Arya Industries, we understand the importance of precision and quality in manufacturing paper rolls. Our machines are designed to meet the highest industry standards, ensuring that the rolls produced are uniform in size, well-formed, and durable. Whether you are producing rolls for packaging, printing, or other commercial uses, our Paper Roll Making Machines deliver superior performance and consistent results.

Advanced Technology

We use cutting-edge technology to manufacture our paper roll machines. Our machines are equipped with advanced features such as automatic speed control, easy operation interfaces, and high-precision rollers, which ensure smooth paper rolling and reduced waste. These machines are built to handle a wide variety of paper types and thicknesses, making them suitable for diverse applications in industries like packaging, printing, and more.

Customization and Versatility

Arya Industries offers a range of paper roll making machines that can be customized based on the specific requirements of the client. Whether you need a machine for producing small rolls, large rolls, or rolls with specific core sizes, we can provide tailored solutions to meet your needs. Our versatile machines can handle different paper materials, including kraft paper, duplex paper, and other specialty papers, ensuring they cater to a wide array of industries.

Easy Maintenance and Durability

One of the key benefits of the Paper Roll Making Machines from Arya Industries is their low maintenance requirements and long-lasting durability. Built with high-quality materials, our machines are designed to withstand the rigors of continuous operation. We also provide comprehensive after-sales services, including maintenance, support, and spare parts, to ensure that your machine operates smoothly for years to come.

Competitive Pricing

Arya Industries offers the best prices for paper roll making machines in Patna, ensuring that businesses of all sizes can invest in high-quality equipment without exceeding their budget. We strive to make our products affordable while maintaining top-notch performance and reliability. Our pricing is transparent, with no hidden costs, so you can be confident you are getting value for your money.

Why Choose Arya Industries?

Leading Provider: Arya Industries is recognized as the top provider of paper roll making machines in Patna.

Innovation: We incorporate the latest technology to provide efficient and reliable machines.

Customization: Machines are customizable to suit your unique production needs.

Affordable Pricing: We offer competitive rates without compromising on quality.

Customer Support: Our excellent after-sales service ensures your machine keeps running smoothly.

In conclusion, Arya Industries is your go-to destination for Paper Roll Making Machines in Patna. Whether you're starting a new venture or looking to upgrade your existing setup, our machines will help you enhance productivity and efficiency. With unmatched quality, durability, and affordability, Arya Industries continues to lead the way in the paper machinery industry.

0 notes

Text

Streamline Workflows With Intelligent Document Processing Tools

Does your office resemble a scene from a filing cabinet explosion? Paperwork piling up, invoices taking weeks to process, and forms languishing in a bureaucratic black hole? These document-related woes are all too familiar for many businesses. But fear not, there's a solution that goes beyond simply buying more filing cabinets: intelligent document processing tools.

These innovative solutions, powered by cutting-edge technology, are revolutionising document handling. Imagine having best intelligent document processing software that can automatically extract key information from invoices, contracts, passports, and even handwritten notes! You'd be looking at a dramatic boost in efficiency, accuracy, and overall productivity.

So, how exactly do Intelligent Document Processing Tools work their magic? Let's delve into the captivating world of IDP and explore its potential benefits for your business.

The Power of Artificial Intelligence (AI)

At the core of IDP lies the power of AI. These smart tools leverage advanced machine learning algorithms to "understand" documents. This goes beyond simple Optical Character Recognition (OCR), which merely converts scanned images into text. IDP tools can:

Classify Documents: They can automatically recognise the type of document it's dealing with, be it an invoice, a purchase order, or a customer application form.

Extract Data: IDP tools can pinpoint specific data points within the document, such as invoice amounts, customer details, or product codes.

Process Complex Layouts: Say goodbye to meticulously structured forms! IDP tools can handle documents with varying layouts and formats, extracting data even from tables and embedded images.

Benefits Beyond Efficiency

While the time-saving and labour-free aspects of Best Intelligent Document Processing Software are undeniably appealing, the advantages extend far beyond streamlining workflows. Let's explore some key benefits you can expect:

Enhanced Accuracy: Human error is inevitable in manual document processing. IDP tools, however, minimise this error by automating data extraction, leading to a significant improvement in data accuracy.

Improved Compliance: With consistent and accurate processing, IDP tools can help ensure compliance with various regulations. This is especially valuable for industries with stringent data management requirements.

Faster Decision Making: Extracted data can be readily integrated with existing business systems. This empowers faster access to crucial information, giving businesses a vital edge in making informed decisions.

Enhanced Customer Experience: Intelligent document processing tools can expedite document processing, leading to faster customer onboarding, smoother financial transactions, and improved overall customer satisfaction.

Choosing the Right Tool for Your Needs

There's no one-size-fits-all solution in the world of IDP. Envistudios, however, offers a diverse range of intelligent document processing solutions. Our team will work closely with you to understand your specific needs and tailor an IDP solution that flawlessly integrates with your existing workflows.

Whether you're a small business struggling with a backlog of invoices or a large enterprise managing complex customer onboarding processes, Envistudios has the IDP solution to empower your business.

Ready to Tame the Paper Tiger?

If you're looking to break free from the shackles of manual document processing and unlock the potential of intelligent automation, contact Envistudios today. We can help you implement a cutting-edge IDP solution that streamlines workflows, improves accuracy, and saves your business valuable time and resources. Get ready to conquer the paper chase and embrace a world of efficient document management.

Original Source - https://medium.com/@aisolutions907/streamline-workflows-with-intelligent-document-processing-tools-f8418c872978

0 notes

Text

Transwind Technologies Pvt Ltd - Reliable Winding Solutions

We are an indigenous manufacturer of Transformer Coil Winding Machine. Since, 2012 our journey has been wonderful and today we standing as one of the major competitors in the industry. We manufacture a wide range of products from manual, semi-automatic to fully automatic machines.

• LV Foil Winding Machine

• HV Foil Winding Machine

• LV Strip Conductor Winding Machine

• HV Coil Winding Machine (Graded Layer / Full-width Paper Insulation)

• HV Coil Winding Machine (Semi-Automatic)

• Edge Winding Machine

• Core Winding Machine

• Bench Top Linear Winding Machines

• Toroidal Coil Winding Machine

• Lamination Core Cut to Length Line

• Special Purpose Machines

• Line Automation

With very well experienced manpower in the field of transformer winding machines and with all in house design capabilities both mechanical and Electrical, we can support on end to end solutions by offering cost-effective and Reliable winding solutions for your requirement with a strong after-sales support.

Visit our website: https://www.transwindtech.com/about-us.php

#transwindtechnologies#transformers#transformerwindingmachines#windingmachine#coilwindingmachine#foilwindingmachine#edgewinding#windingmachinemanufacturers#transwindtech

0 notes

Text

Our Factory OPP Tape for Packing for our Angola Customers 40ft HQ container order

Zhejiang Jinke Adhesive Products Co., Ltd is a professional Adhesive Tape manufacturer and Supplier. The company has fully automatic intelligent control of 100,000 tons of acrylic water-based glue production equipment, 8 lines High-speed coating line, 5 professional printing machines, more than 50 sets of multi-type automatic cutting equipment, 1 set of paper core production line.

0 notes

Text

Unlocking Efficiency: The Power of Online Summarization with Zerogpt

In today's fast-paced digital world, information overload is a common challenge that many individuals face. With an abundance of content available online, from articles and research papers to news articles and blog posts, extracting key insights efficiently has become more crucial than ever. Enter Zerogpt, the innovative brand revolutionizing the way we online summarize. With its advanced online summarise tools and PDF Summarizer capabilities, Zerogpt empowers users to distill large volumes of text into concise summaries with unparalleled speed and accuracy.

The Need for Efficient Online Summarization

As the volume of information available online continues to grow exponentially, finding the most relevant and valuable insights amidst the noise can be a daunting task. Whether you're a student conducting research, a professional keeping up with industry trends, or a reader looking to stay informed, the ability to online summarize efficiently is essential for maximizing productivity and extracting actionable insights. Traditional methods of manual online summarising are time-consuming and labor-intensive, making them impractical for processing large volumes of text quickly. This is where Zerogpt steps in, offering a solution that combines the power of artificial intelligence with the convenience of online tools to streamline the summarization process.

Introducing Zerogpt: Your Online Summarization Companion

Zerogpt emerges as a game-changer in the realm of online summarization, offering a suite of advanced tools and features designed to simplify the process of extracting key insights from text. At its core lies its innovative online summarization platform, which leverages cutting-edge machine learning algorithms and natural language processing techniques to analyze text and generate concise summaries automatically. Whether you're dealing with articles, research papers, or PDF documents, Zerogpt provides you with the tools you need to distill complex information into digestible nuggets of knowledge quickly and efficiently.

The Power of Online Summarization

With Zerogpt's online summarization capabilities, users can significantly reduce the time and effort required to process large volumes of text. Whether you're scanning through lengthy articles or sifting through dense research papers, Zerogpt's summarise text online enables you to extract the most important information quickly and effectively. By condensing complex ideas into succinct summaries, Zerogpt empowers users to focus their attention on the most relevant insights, facilitating better decision-making and enhancing overall productivity.

Effortless PDF Summarization

In addition to its online summarization platform, Zerogpt offers a powerful PDF summarizer tool that enables users to extract key insights from PDF documents with ease. Whether you're dealing with reports, whitepapers, or academic journals, Zerogpt's PDF summarizer automatically analyzes the text and generates concise Online Summarise that capture the essence of the document. By eliminating the need for manual summarization, Zerogpt's PDF summarizer streamlines the process of extracting insights from PDF documents, saving users valuable time and effort.

The Zerogpt Advantage: Speed, Accuracy, and Convenience

At its core, Zerogpt embodies a commitment to speed, accuracy, and convenience in summarise text online. Whether you're a student, researcher, or professional, Zerogpt provides you with the tools you need to extract key insights from text quickly and effectively. By harnessing the power of artificial intelligence and natural language processing, Zerogpt empowers users to navigate the vast sea of information available online with confidence and ease. With Zerogpt as your online summarization companion, you can unlock new levels of efficiency and productivity in your quest for knowledge.

Conclusion: Embracing the Future of Online Summarization with Zerogpt

As the volume of information available online continues to grow, the need for efficient summarization tools has never been greater. With its advanced online summarization platform and PDF summarizer capabilities, Zerogpt offers a solution that combines speed, accuracy, and convenience to help users extract key insights from text quickly and effectively. Whether you're a student, researcher, or professional, Zerogpt empowers you to stay informed, make better decisions, and unlock new opportunities in the digital age. Embrace the future of online summarization with Zerogpt and discover a world of knowledge at your fingertips.

0 notes

Text

Robus India's Automatic Reel-to-Sheet Film Lamination

Tired of slow, labor-intensive laminating processes? Robus India's Automatic Reel-to-Sheet Film Lamination machine is here to revolutionize your workflow. This cutting-edge technology takes laminating to the next level, delivering unmatched efficiency, superior quality, and increased productivity for a wide range of applications.

Here's why Robus India's laminating machine is a game-changer:

Ditch the tedious: Say goodbye to manually loading sheets.

Continuous film feed keeps your production flowing smoothly.

Precision matters: Ultrasonic and CCD web guiding systems ensure flawless alignment, minimizing waste and maximizing yield.

Quality you can trust: Double heating systems and pneumatic pressure control create bubble-free, wrinkle-free, and perfectly bonded laminates.

Versatility unleashed: Laminate a diverse range of materials from PVC to thermal films, meeting all your needs.

High-speed, high-volume: Boost your output and keep pace with your demanding production requirements.

Effortless operation: Intuitive controls and easy maintenance minimize downtime and maximize efficiency.

Robus India's machine goes beyond the basics with its advanced features:

Effortless loading: The shaftless unwinding system handles jumbo rolls of film with ease, accommodating both 3" and 6" paper cores.

Precision cutting: Get accurate sheet sizes every time with the high-precision, servo-driven slitting system, reducing waste and maximizing material utilization.

Organized workflow: The automatic stacking function neatly collects finished sheets, keeping your production area organized and efficient.

Built to last: Robust engineering and premium materials ensure long-lasting performance and minimal maintenance, giving you a reliable partner for years to come.

Why Investing in Robus India' s Reel to Sheet is More Than Just Buying a Machine - It' s Investing in Your Business' s Future:

Robus India' s Automatic Reel to Sheet Film Lamination machine isn' t just another piece of equipment - it' s a strategic investment in your company' s success and growth across multiple dimensions.** Here' s how:**

Boosting Your Bottom Line:

Production Volume Skyrockets: Ditch slow manual sheet loading and embrace continuous film lamination for significantly higher output volumes and shorter turnaround times.** Meet deadlines with ease and keep your customers happy with faster deliveries.**

Profitability Takes Flight: Increased production translates to bigger revenue streams.** Reduce material waste with precise cutting and flawless lamination quality.** Additionally,** minimize labor costs by eliminating manual sheet loading and streamline operations with intuitive controls and reduced downtime.**

Enhancing Customer Satisfaction:

Top Quality Every Time: Impress your customers with consistently perfect laminates achieved through double heating systems and precise pressure control.** Bubble and wrinkle free results mean a professional look and feel that builds brand trust.**

Versatility Meets Demand: Cater to diverse needs with the ability to laminate a wide range of materials.** Whether it' s PVC for packaging or thermal films for industrial applications,** Robus India' s machine tackles them all with ease.**

Operating at Peak Efficiency:

Workflow Optimized: Automatic stacking systems keep your production area organized and efficient,** reducing downtime and increasing productivity.** Intuitive controls simplify operation for your team,** minimizing training time and ensuring smooth workflows.**

Minimize Downtime: Robust engineering and premium materials ensure reliable performance,** so you can focus on production and forget about constant maintenance headaches.**

Investing in adaptability: Changing market needs are no match for Robus India' s versatility.** Whether you need to switch film types or adjust sheet sizes,** this machine adapts quickly and easily,** keeping your business nimble and responsive.**

The Choice is Clear: Invest in Your Future

Robus India's Automatic Reel-to-Sheet Film Lamination machine isn't just about laminating sheets – it's about propelling your business to the next level. Increased production, enhanced quality, reduced costs, and improved workflow all combine to unlock your full potential and drive profitable growth.

Website: https://www.robusindia.com/

Address: Plot No. 8, Udyog Kendra-2, Ecotech-3, Greater Noida, Gautam Buddha Nagar, (U.P) 201308

Content: +91-9810119683 +91-9899118637

0 notes